The team in the UK is investing in advanced technologies such as digital manufacturing, 3D printing, and the use of virtual and augmented reality which are evolving how Typhoon is produced. This is supporting the development of technologies which are considered key to defining how a future combat aircraft will be manufactured.

This investment is not only allowing us to manufacture quicker and cheaper, it is enhancing the quality of the components we produce and giving us better data to ensure we can support the aircraft through its life.

Here Andy tells picks out some examples where improvements in processes, technology and materials are being embedded in BAE Systems’ Eurofighter Typhoon production today — with one eye on the future.

Additive manufacturing: Using advanced additive manufacturing to certify the first titanium parts for the Eurofighter Typhoon which will form part of the structure which surrounds the engines of the jet. Traditionally, parts would be fabricated and welded together, whereas now they are additive manufactured using titanium as one part, delivering cost and time savings and enhancing quality.

Environmental Cooling System (ECS) duct: This cooling duct is an example of additive manufacturing in use on Eurofighter Typhoon today, where it is used to provide cooling for the aircraft’s new electronically-scanning radar. The part was previously made of 16 pieces assembled together. The new revised part is now made in two pieces ofusing an advanced nylon material which and takes 24 hours to build and two aircraft sets can be printed in one build

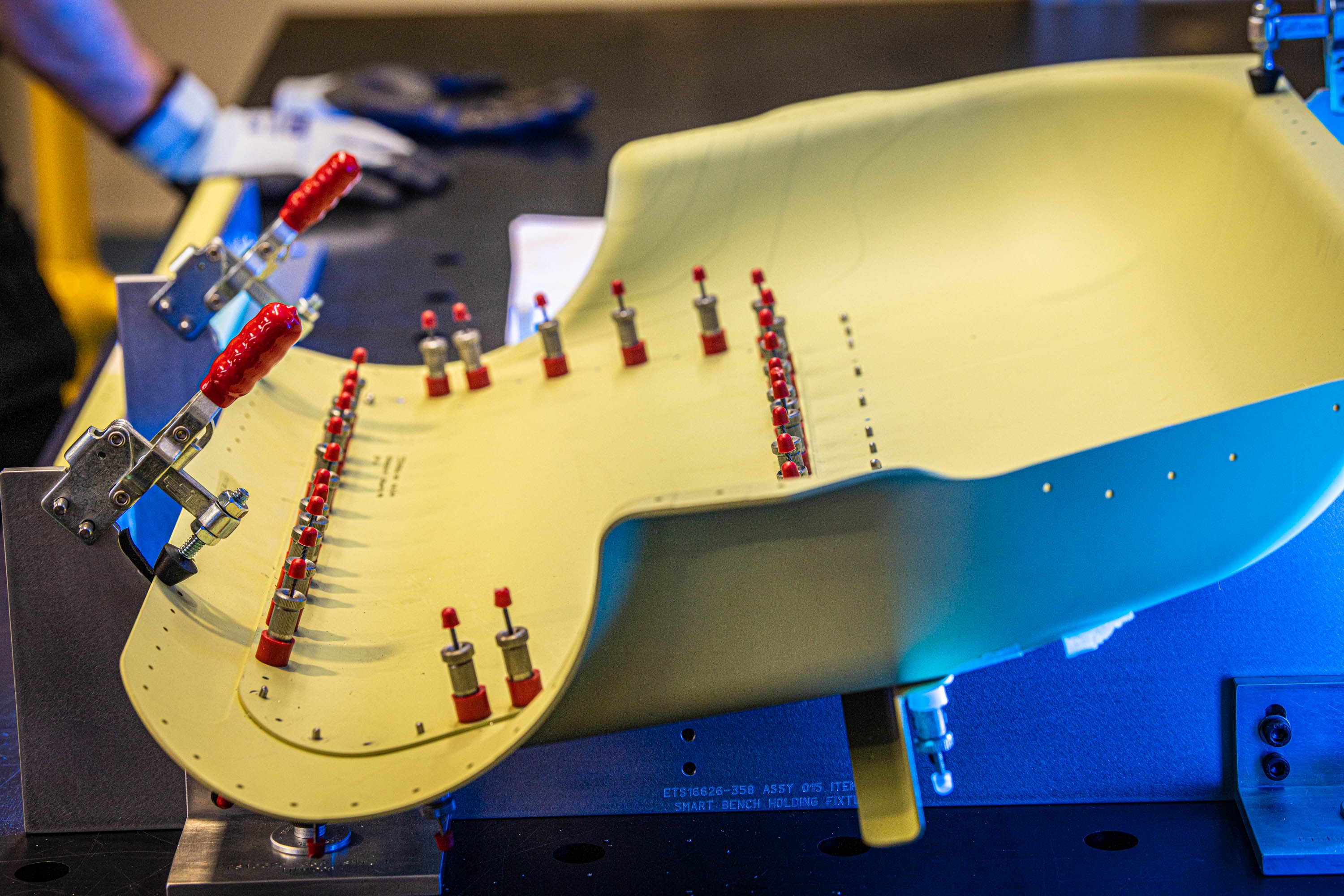

Optical Projection on Typhoon fin: Optical projection technology is being used to support operators to insert fasteners on to Typhoon fins. It delivers information at the point of use including measurement and fastener type information, ensuring the process is faster and more efficient.

Automated looms: Through the digitisation and automation of producing electrical wiring looms for the 12 kilometres of wire which goes in to the front fuselage of Typhoon, the team is saving five kilometres of wire which would have been wasted.

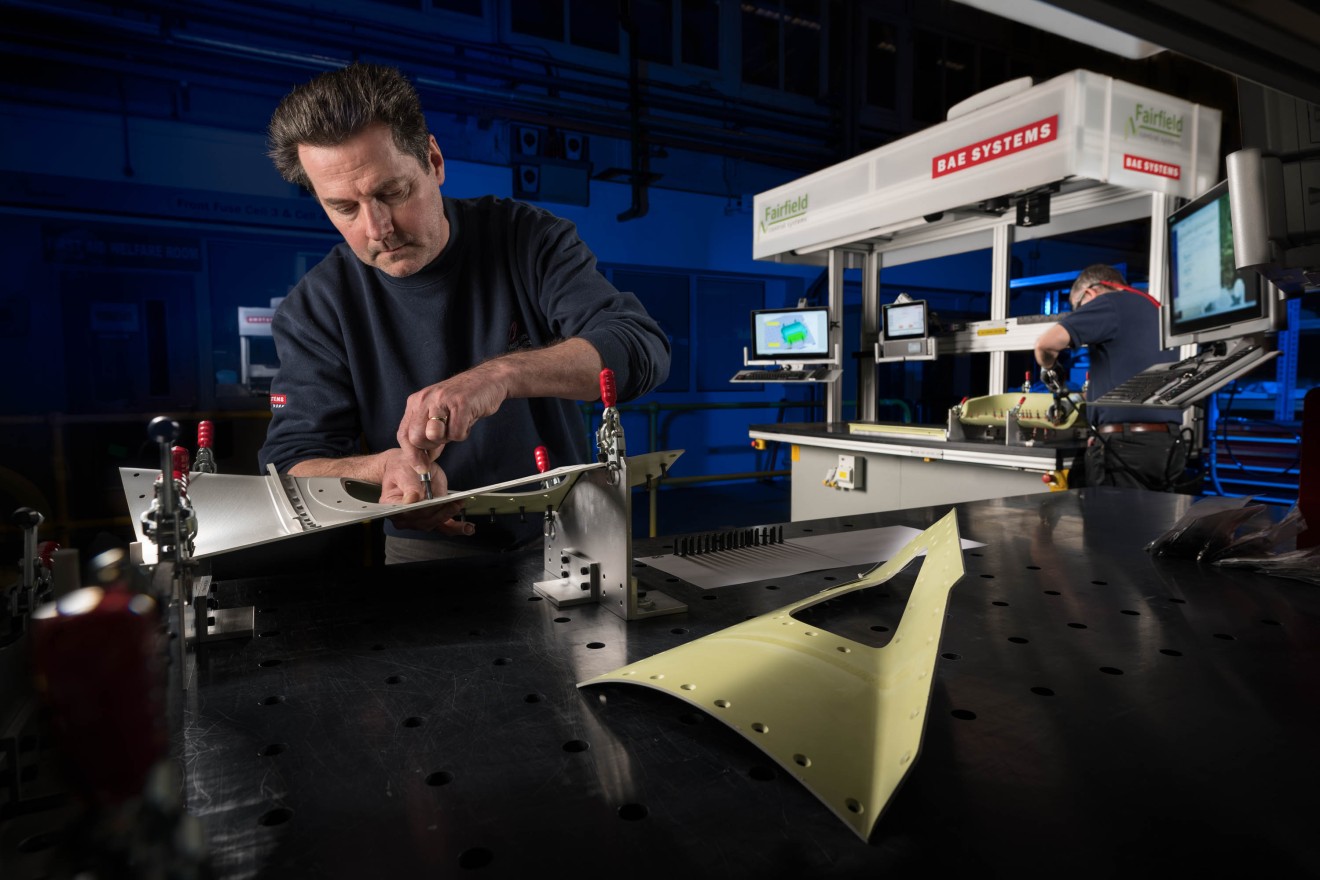

The Intelligent Workstation

In the BAE Systems Typhoon production facility in Samlesbury, UK, an Intelligent Workstation is already in use to produce sub-assemblies for our export aircraft deliveries to our customers in Kuwait and Qatar.

These workstations are equipped with a range of technologies which assist operators to assemble components, in a more efficient way.

In development in the BAE Systems Factory of the Future, are a range of technologies which include 'pick by light' technology prompting the user towards the correct components or consumables, and a sensor-enabled cobotic arm to work safely and seamlessly alongside our people.

We can expect some of these further technologies to be brought in to use for the production of components for future Typhoon aircraft, including the up to 38 aircraft due to be delivered to the German Air Force